Company History

Aluminium Alloy Industries

- Supply of Alloy Wheel to PROTON for Model Wira, Waja, with Wheel Casting source from Bahrain, Indonesia and Thailand.

Aluminium Alloy Industries

- Sales of Aftermarket Wheels for Domestic market

- Manufacture of Machine valves for Oil & Gas Industries

Aluminium Alloy Industries

- Commencement of Alloy Wheel Casting Plant using Gravity Casting Process, and ALSi11 Alloy (No Heat Treatment)

Aluminium Alloy Industries

- Acquired License from GmbH for MAGMA Casting Solutions for Casting Simulation and Mold Designs.

- Acquired Automatic ONLINE X-Ray Inspection Machine with Auto Defect Recognition (ADR), GmbH Purchased of T6 Treatment Facility.

- Commencement of manufacturing using A356.2 alloy with T6 Heat treatment and install LP Alloy wheel Casting Line, Automatic Painting Line, Diamond Cut Machines

Aluminium Alloy Industries

- Supply to Proton very 1st Diamond-cut face Wheel for Model Suprima-S Hatchback

Aluminium Alloy Industries

- Commencement of supply to Honda Malaysia for Torque Rod Brackets

- Commencement of export for REM wheels to USA

Aluminium Alloy Industries

- Commencement of supply of Proton New Persona wheels and Exora MC’s

Aluminium Alloy Industries

- Commencement of supply of Proton Preve MC models

- Commencement of supply of Alloy Wheels for Honda Malaysia for BR-V models

Aluminium Alloy Industries

- Technical Contract with KUNSHAN LIUFENG MACHINERY CO., LTD (China)

Our Product

Diamond Cut 17×7.5″ with Matte Finishing

Engine Mount

Gear Case

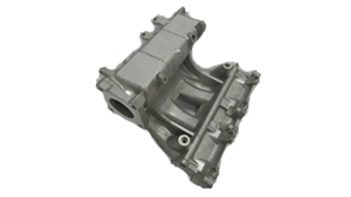

1.8 Intake Mainfold

Diamond Cut 16x6J with Gloss Finishing

Full Paint 16×6.5J with Gloss Finishing

Full Paint 17×7.5J with Gloss Finishing

Diamond Cut 15x6J with Matte Finishing

After Market Wheel 17x7J

After Market Wheel 16x7J

After Market Wheel 17x7J

After Market Wheel 17x7J

Our Facilities

Direct Drive Spindle CNC High

Speed Lathe Machine Capable to Produce Mirror Finish of the Front Face Design

N/A

VERTICAL CNC Machining Center-4 Units ARES Seiki

N/A

N/A

360° Rotary Stand Alone Manipulator

LP Casting Machines

Homel Furnace with Online Nitrogen Degassing

Offline Nitrogen Degassing

LP Casting Line-Melt Transfer

Fully Automatic Wet Painting Bell Gun System (Base coat and Top coat)

Batch Type Heat Treatment Furnace

Continuous Type Heat Treatment Furnace

Machining Line-Horizontal & Vertical CNC Lines

10 Stages Chrome Free Pretreatment Line

Powder Coating Line

Quality Certificate & Accreditation

Contact Us

ALUMINIUM ALLOY INDUSTRIES

Lot 2473, Nilai Industrial Estate

71800 Nilai,

Negeri Sembilan Darul Khusus

Malaysia

Tel: +6 06-7994570

Fax: +6 06-7994566

E-mail : cmlee@aai.com.my

CONTACT PERSON

LEE CHEN MAU

President & CEO

Mobile : +6012-235 9989

Tel: +606-7994570

E-mail : cmlee@aai.com.my

LIEW WOEI YAW

Production Manager

Mobile : +6017-922 1857

Tel: +606-7994570

E-mail : wyliew@aai.com.my